How Today’s Technology Allows Manufacturers to Innovate

Did you know that by 2030, it is projected that the global manufacturing technology market will exceed $700 billion? This staggering statistic underscores the profound impact of modern manufacturing technology in driving innovation in manufacturing processes. As manufacturers face increasing demands for efficiency and customization, integrating today’s technology has become not just an advantage, but a necessity. From automating production lines to employing data analytics and IoT solutions, these advancements are reshaping how manufacturers operate and compete in the marketplace.

Today’s technology allows manufacturers to innovate like never before, pushing the boundaries of what’s possible in terms of production speed, quality, and adaptability. Embracing these advancements not only enhances production efficiency, but also fosters a culture of continuous improvement, which is vital in an ever-evolving industry. In this article, we will explore the multifaceted benefits of modern manufacturing technologies and how they play a crucial role in transforming the manufacturing landscape.

Key Takeaways

- The global manufacturing technology market is expected to surpass $700 billion by 2030.

- Modern manufacturing technology enhances productivity and innovation.

- Adapting to technological changes is essential for manufacturers to remain competitive.

- Integration of automation and data analytics leads to improved efficiency.

- Embracing new technologies fosters a culture of continuous improvement.

- Technological advancements not only improve production but also help in customization.

Introduction to Modern Manufacturing Technology

Modern manufacturing technology plays a crucial role in the evolution of production systems. By leveraging advanced manufacturing techniques, businesses can significantly enhance their productivity and streamline operations. The landscape of manufacturing has undergone a remarkable transformation, where innovation is at the forefront of meeting consumer demands and remaining competitive.

Key areas of focus in modern manufacturing technology include automation, robotics, and artificial intelligence. These technologies not only help in reducing waste but also drive efficiency in various processes. The shift from traditional methods to more sophisticated techniques marks a significant step toward achieving manufacturing innovation. With this advancement, manufacturers can maximize output while minimizing costs.

Examining the impact of these technologies reveals a future where productivity is optimized through complex systems integrating seamlessly into everyday operations. As companies embrace these innovations, they refine their approach to manufacturing, setting new standards for quality and responsiveness in the global marketplace.

The Role of Digital Transformation in Manufacturing

Digital transformation in manufacturing plays a pivotal role in reshaping how companies operate and compete in today’s fast-paced environment. With the incorporation of digital technology in production, manufacturers are moving towards smarter factories that utilize real-time data to enhance efficiency and agility.

Technologies such as cloud computing, the Internet of Things (IoT), and big data analytics allow manufacturers to streamline processes significantly. These advancements enable data-driven decision-making, which not only reduces operational costs but also improves product quality.

Case studies from industry leaders highlight the benefits of embracing digital transformation in manufacturing. Companies that have adopted these innovative technologies report increased productivity and better resource management. For instance, a leading automobile manufacturer utilized IoT sensors to monitor equipment health, resulting in a noticeable reduction in downtime and maintenance costs.

As the manufacturing industry transformation continues, businesses are realizing the importance of integrating these digital tools into their operations. The shift towards a digitally equipped workforce signifies a crucial step in remaining competitive and responsive to market demands.

Advanced Technology for Production: A Game Changer

In the rapidly evolving landscape of manufacturing, advanced technology for production has emerged as a true game changer. Innovations such as artificial intelligence (AI), machine learning, and additive manufacturing have revolutionized production processes, enabling manufacturers to attain significant production efficiency improvements. These manufacturing technology advancements allow for streamlined operations, where machines can analyze data and make real-time adjustments to enhance output.

Manufacturers leveraging these technologies experience increased flexibility in their production lines. The shift from traditional mass production techniques to more customized solutions becomes feasible through these advancements. For instance, AI-driven analytics can predict demand trends, allowing companies to adjust their production strategies effectively. As a result, producers can respond more quickly to market changes, optimizing resource allocation and minimizing waste.

Evidence of the impact of these transformations can be seen in numerous case studies where companies have integrated advanced technology for production. A leading automotive manufacturer recently reported a 30% reduction in production time after implementing robotic automation and AI systems, showcasing the tangible benefits of these innovations. The deployment of such cutting-edge technologies not only enhances product quality but also fosters a culture of continuous improvement, driving manufacturers towards future success.

How Automation is Revolutionizing Manufacturing Processes

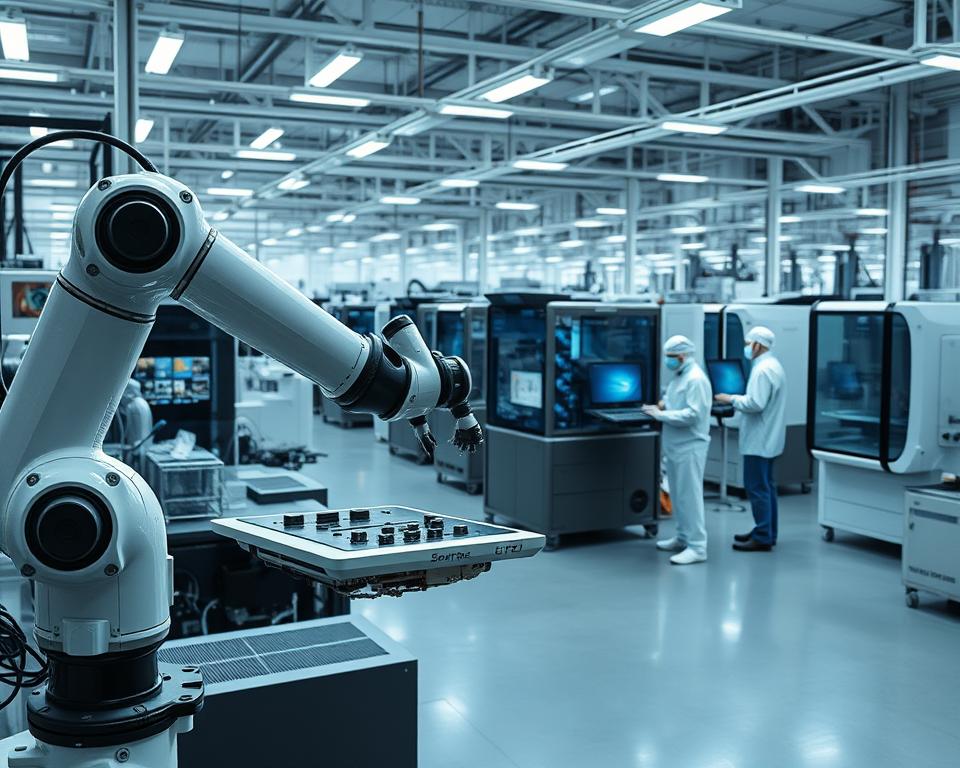

Automation in manufacturing serves as a cornerstone of contemporary production strategies, reshaping how tasks are completed on the factory floor. Modern manufacturing process innovation heavily relies on various forms of automation, including robotic process automation, which allows for seamless integration of machines into traditional workflows.

Robotic arms, often seen working tirelessly on assembly lines, exemplify how automation enhances efficiency. These machines operate with incredible precision and speed, reducing the likelihood of human error and ensuring a higher level of output. Manufacturers can focus on complex problem-solving tasks, delegating repetitive and hazardous jobs to automated systems.

The adoption of fully automated factories marks a significant advancement in production capabilities. Leading automakers like Toyota and electronics giants such as Samsung have already reaped substantial benefits from implementing automation in their manufacturing processes. These innovations allow for increased production rates and substantial cost savings.

| Advantages of Automation | Traditional Methods |

|---|---|

| Higher Speed | Moderate Speed |

| Reduced Error Rate | Higher Error Rate |

| Increased Safety | Safety Risks |

| Lower Labor Costs | Higher Labor Costs |

In summary, automation in manufacturing stands as a pivotal element in driving productivity and innovation. By integrating advanced technology like robotic process automation, companies can not only enhance their operational efficiency but also create safer working environments for their employees.

Today’s Technology Allows Manufacturers to Enhance Efficiency

Modern manufacturing thrives on the integration of innovative solutions designed to boost technology efficiency in manufacturing. As manufacturers face increasing pressure to optimize productivity, implementing smart technology can significantly enhance operational processes. By harnessing the power of IoT devices and smart sensors, companies can achieve real-time monitoring and streamline operations effectively.

Streamlining Operations with Smart Technology

Smart technology for manufacturers transforms traditional production methodologies. Utilizing connected devices allows for data collection from various points along the production line. This data informs operational adjustments in real time, reducing waste and enhancing workflow. Companies like Siemens have employed smart technology to create responsive systems that adapt to changing demands, leading to more agile operations.

Reducing Downtime through Predictive Maintenance

Predictive maintenance emerges as a crucial strategy in minimizing unforeseen equipment failures. By analyzing data trends, manufacturers can predict when machines are likely to fail and perform maintenance proactively. This approach not only extends equipment lifespan but also saves costs associated with unplanned downtimes. For instance, General Electric uses predictive analytics to optimize their maintenance schedules, achieving considerable improvements in productivity.

The successful integration of smart technology and predictive maintenance illustrates how today’s technological advancements can drive significant efficiency gains in the manufacturing sector. As companies continue to adapt, they set a new standard for operational excellence in an ever-evolving industry landscape.

Embracing Industry 4.0 for Better Innovation

Industry 4.0 marks a significant shift in the manufacturing landscape, driven by the integration of digital technologies into traditional manufacturing processes. This revolutionary approach reshapes production with innovative manufacturing practices that enhance efficiency, productivity, and responsiveness to market demands. Cyber-physical systems, IoT, cloud computing, and cognitive computing are key components that define this new era.

The concept of digital disruption in manufacturing transforms how businesses operate. Smart factories leverage real-time data and environments that adapt automatically to optimize workflows. Companies embracing Industry 4.0 can streamline processes and reduce operational costs while enhancing product quality. For instance, manufacturers can implement predictive analytics to foresee equipment failures, thus minimizing downtime and boosting overall productivity.

In practice, organizations that adopt Industry 4.0 principles are not just keeping up; they are leading the charge towards future innovations. Enhanced connectivity between machines and systems enables unprecedented levels of customization and collaboration. As a result, manufacturers can create new business models that align with consumer expectations and industry standards.

The Importance of Data Analytics in Manufacturing

Data analytics in manufacturing serves as a transformative tool that helps companies streamline operations and enhance output quality. As manufacturers face increased pressures to optimize processes, the utilization of big data enables real-time decision-making, allowing for swift adjustments to production lines and responses to market dynamics.

Real-Time Decision Making with Big Data

The significance of big data usage in manufacturing cannot be overstated. By aggregating data from various sources, manufacturers can derive insights that inform operational decisions on the fly. For instance, sensors embedded in machinery collect data on performance metrics, which can highlight potential issues before they escalate. Real-time analytics empowers manufacturers to respond promptly, reducing inefficiencies and saving costs.

Improving Quality Control through Analytics

Quality control improvements are another vital aspect of data analytics in manufacturing. By analyzing production data, manufacturers can identify patterns and anomalies that could lead to defects. Companies like Bosch utilize advanced analytics techniques to monitor product quality throughout the production cycle. This not only minimizes the risk of defects reaching customers but also reinforces customer loyalty as a result of consistent quality assurance.

| Company | Analytic Technique | Outcome |

|---|---|---|

| Bosch | Predictive Analysis | Reduced defect rates by 20% |

| General Electric | Real-Time Monitoring | Increased production efficiency by 15% |

| Siemens | Machine Learning | Improved quality metrics by 30% |

Smart Technology for Manufacturers: IoT Integration

The integration of smart technology for manufacturers is transforming the landscape of production through advanced IoT integration in manufacturing. This technology enhances communication between machines and devices, creating more efficient and responsive connected manufacturing systems. By harnessing data from various sources, manufacturers can gain critical insights into their operations, greatly improving productivity and operational efficiency.

The implementation of IoT in manufacturing allows real-time monitoring of equipment performance. This connectivity not only streamlines processes but also enables predictive maintenance, reducing unexpected downtimes. Through effective use of smart technology, manufacturers can respond quickly to any production issues, fostering a culture of continuous improvement.

Connected manufacturing systems facilitate asset tracking, inventory management, and resource allocation. A well-integrated IoT framework empowers manufacturers to optimize logistics and enhance supply chain management, which is crucial in today’s fast-paced market. As these technologies evolve, manufacturers that adapt will foster greater innovation and sustainability in their practices.

Collaborative Robotics: The Future of Workforce Innovation

The rise of collaborative robotics is shaping the future of workforce innovation across various industries. These robots, often referred to as cobots, are designed to work alongside human operators, enhancing productivity while ensuring safety. Unlike traditional robots that operate independently, cobots actively assist employees in their tasks, bridging the gap between human skills and automation.

Many sectors are embracing collaborative robotics to improve operations. For instance, in the automotive industry, cobots assist with assembly tasks, providing support to workers without displacing them. This integration of robots in manufacturing is pivotal, as it allows for greater flexibility and adaptability to changing production needs.

The benefits of collaborative robotics extend beyond mere efficiency. By enhancing the dynamic between human labor and automation and workforce strategies, businesses can foster a more innovative work environment. Cobots support tasks such as packaging, quality control, and material handling, leading to increased output and reduced errors.

As industries recognize the advantages of cobots, the adoption of collaborative robotics will likely continue to grow, shaping the future of manufacturing and workforce dynamics.

Sustainability through Modern Manufacturing Practices

Sustainability takes center stage in today’s manufacturing landscape, as businesses increasingly commit to sustainable manufacturing practices. Companies are adopting eco-friendly manufacturing technologies that not only minimize waste but also enhance energy efficiency throughout production processes.

The integration of green technology in production facilitates a shift toward responsible sourcing and the use of sustainable materials. For example, companies like Tesla have pioneered innovative methods that emphasize recycling and reusing materials, making strides in reducing their carbon footprint.

Organizations committed to sustainability often report benefits that extend beyond environmental impacts. By embracing sustainable manufacturing practices, companies experience increased brand loyalty, improved customer satisfaction, and potential cost savings from energy-efficient operations.

| Company | Sustainable Practice | Impact |

|---|---|---|

| Patagonia | Use of recycled materials in apparel | Minimized resource extraction and waste |

| Unilever | Reducing plastic use with alternative packaging | Enhanced environment protection |

| Ford | Investing in energy-efficient manufacturing plants | Lower operational costs |

As the industry evolves, the collaboration between manufacturers and technology providers proves crucial. This partnership transcends merely adopting new eco-friendly manufacturing technologies. It’s about redefining production processes in pursuit of a sustainable future.

Custom Manufacturing Solutions with Today’s Technology

Modern advancements in manufacturing offer unprecedented opportunities for customization. Custom manufacturing solutions empower businesses to create products tailored to specific customer needs. With the rise of 3D printing technology, manufacturers can respond more swiftly to individual requests, facilitating a shift towards on-demand manufacturing.

3D Printing and On-Demand Production

3D printing technology revolutionizes the production landscape by enabling on-demand manufacturing. This innovation reduces the need for extensive inventory while allowing manufacturers to produce parts and products quickly. The flexibility of 3D printing means that businesses can cater to unique design specifications without incurring significant costs or delays, making it an invaluable asset in a competitive market.

Mass Customization for Customer Satisfaction

Mass customization represents a fusion of personalization and large-scale production. Through advanced manufacturing techniques, companies have the ability to deliver products that perfectly align with customer expectations. This approach enhances customer satisfaction and builds brand loyalty. Utilizing custom manufacturing solutions allows manufacturers to implement this strategy seamlessly, ensuring that every item meets precise requirements.

Enhancing Safety Standards with Modern Technology

Ensuring health and safety in production remains a top priority for manufacturers. Modern technology increasingly contributes to enhanced safety standards, significantly transforming the work environment. Key innovations such as workplace safety technology play a vital role in minimizing risks and preventing accidents. For instance, the integration of wearables allows employees to monitor vital signs and receive instant alerts if unsafe conditions arise.

Surveillance systems have become more sophisticated, enabling real-time monitoring of workplace activities. By leveraging advanced analytics, companies can pinpoint areas needing safety improvements in manufacturing. These insights determine where enhancements are necessary, allowing managers to intervene proactively.

Automation is another significant factor in enhancing safety. Automated processes reduce the need for human involvement in hazardous tasks, effectively lowering the injury risk. Alongside technological advancements, training programs incorporating virtual reality bring a new dimension to employee education, ensuring that workers are well-prepared to navigate their environments safely.

Cultivating a Culture of Continuous Improvement

Establishing a robust manufacturing efficiency culture is essential for thriving in today’s competitive landscape. Continuous improvement in manufacturing must be engrained within the organization, prompting teams to constantly seek ways to enhance processes. Lean manufacturing principles play a pivotal role in this journey, focusing on minimizing waste while maximizing value.

Encouraging employee involvement is a cornerstone of cultivating this culture. When workers feel empowered to contribute ideas and provide feedback, it fosters a proactive atmosphere ripe for innovation. Implementing regular meetings and brainstorming sessions can inspire collaborative efforts in identifying inefficiencies and suggesting improvements. Small, incremental changes often yield significant results over time.

Tracking progress is necessary for reinforcing a continuous improvement mindset. Metrics and KPIs can gauge the effectiveness of implemented lean manufacturing principles, helping to define success and areas for further refinement. Recognizing and celebrating achievements can motivate teams, linking their contributions to larger business objectives.

Challenges and Considerations in Technological Adoption

Manufacturers looking to innovate through technology encounter various challenges in manufacturing technology. The transition to advanced systems may introduce complications that hinder progress. Understanding these difficulties is crucial for success.

Cost is often a primary concern when businesses consider tech adoption. New technologies can require significant investments, making it essential to weigh potential benefits against financial constraints. Manufacturers must evaluate the long-term value of these technologies in relation to immediate costs.

Another notable barrier is the shortage of skilled labor. As technology becomes more complex, finding qualified personnel to manage, operate, and maintain new systems can be challenging. This skill gap creates a roadblock in implementing innovative solutions effectively.

Resistance to change within an organization can further complicate the adoption of new technologies. Employees may feel apprehensive about shifting from familiar processes to unfamiliar tools. Building a culture that embraces change requires clear communication and training programs to facilitate smooth transitions.

| Challenges | Description | Strategies for Overcoming |

|---|---|---|

| Cost | High initial investment for new technology | Conduct cost-benefit analyses, explore financing options |

| Lack of Skilled Labor | Difficulty in finding or training employees | Offer training programs, partner with educational institutions |

| Resistance to Change | Employees hesitant to adopt new systems | Implement change management strategies, provide support |

Addressing these manufacturing technology barriers is vital for organizations aiming to stay competitive in a rapidly evolving landscape. Strategic planning and a proactive approach can significantly ease the pathway towards successful tech adoption.

The Future of Manufacturing: Building Resilience with Technology

The manufacturing landscape is rapidly evolving as companies navigate disruptions and strive for adaptability. Central to the future of manufacturing are technology-driven manufacturing evolution and resilient manufacturing strategies. Embracing automation and artificial intelligence allows firms to efficiently manage resources and respond to market shifts.

As manufacturers implement digital twins, they gain real-time insights into production processes, fostering a proactive approach to challenges. This digital integration not only enhances operational efficiency but also amplifies resilience against unforeseen disruptions. The potential of advanced technologies, such as IoT and big data analytics, further supports this transformation.

Many industry leaders are adopting innovative practices to ensure they remain competitive. Key components of these strategies include:

- Automation: Streamlining processes to reduce costs and improve speed.

- Data-driven decision making: Utilizing analytics for optimizing operations and enhancing quality control.

- Collaboration: Engaging employees and partners to foster a culture of innovation.

The future of manufacturing promises to be dynamic, with resilience as its cornerstone. Organizations that prioritize technology integration will likely lead the way, setting new standards for operational excellence.

Conclusion

In the evolving manufacturing landscape, innovation in manufacturing technology has proven to be a driving force behind enhanced operational efficiency and productivity. Throughout this article, we’ve explored the significant role that advanced technologies like automation, IoT integration, and data analytics play in helping manufacturers remain competitive in a global arena. Embracing these innovations is not merely an option; it’s a necessity for businesses aiming to thrive in the future.

As we look towards future manufacturing solutions, the importance of fostering an innovative organizational mindset becomes clear. This investment in technology not only prepares manufacturers to meet current challenges but also equips them to adapt to unforeseen changes. The ability to leverage smart technologies, automate processes, and utilize data effectively is where the future truly lies.

Manufacturers who actively embrace modern practices will undoubtedly set themselves apart in the industry. By prioritizing innovation and continuous improvement, they will not only enhance their operations today but position themselves for sustained growth and success in the years to come.